Cool roofs, also known as reflective roofs, are roof surfaces designed to reflect radiation from the sun, reducing heat transfer into the building.

How do they differ from conventional roofing products?

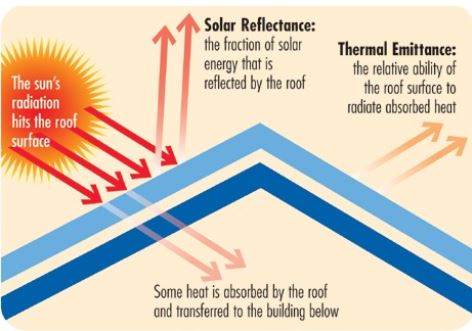

Unlike most North American asphalt roofs, cool roofs are specially engineered to reflect much of the sun’s radiant energy back into space instead of transferring it as heat into the building below. The two basic characteristics that determine the performance of a cool roof are solar reflectance and thermal emittance. Both properties are rated on a scale from 0 to 1, where 1 is the most reflective or emissive. Although there is no industry-wide definition of a cool roof, the EPA’s Energy Star Roof Products Program has established a minimum standard, requiring that cool roof products have an initial reflectance of at least 0.65, and a reflectance of at least 0.5 after three years of weathering. By contrast, conventional asphalt roofs have a reflectivity of between 0.06 and 0.26, resulting in large amounts of heat transfer into the building’s interior.

The use of cool roof products offers the following benefits:

- increased lifetime of roofing materials. Cool roofs do not experience thermal cycling as much as conventional roofs. Thermal cycling can deteriorate the bond between shingles and asphalt, potentially causing premature failure;

- energy savings. According to the U.S. Department of Energy, some reflective roof products can lower roof surface temperature by up to 100 degrees and can reduce peak cooling demand by as much as 15%. Cool roofs may result in increased heating costs during the winter, but this increase is greatly outweighed by the cooling energy savings achieved during summer;

- reduction of the “heat island” effect. This is the tendency for metropolitan areas to be warmer than their surroundings due to the use of building materials that retain heat. Studies have shown that this phenomenon increases the risk of death during heatwaves and decreases air quality by increasing the production of pollutants, such as ozone;

- lower peak electrical demand. The maximum energy load an electric utility experience in order to supply customers instantaneously, which generally occurs in late afternoons during summer as businesses and residences turn up their air conditioners, is reduced by the implementation of reflective roofs; and

Image used by permission of the Cool Roof Rating Council (CRRC

- utility rebates, in some areas. Generally, utilities pay back a certain percentage — usually about $0.20 per dollar — after installation and documentation. Their motivation for these incentives is to reduce the intensity and likelihood of blackouts and brownouts.

Cool Roof Product Types

InterNACHI believes that products generally fall into a few categories: single-ply materials, and coatings. Single-ply materials are large sheets of pre-made roofing that are mechanically fastened over the existing roof, and then sealed at the seams. Coatings are applied using sprays, rollers or brushes over an existing clean, leak-free roof surface. “Cool” versions of asphalt shingles are also available.

These products include:

- Coatings: Roof coatings can be divided into two categories: field-applied and factory-applied. Field-applied coatings are applied directly onto the roof surface, either on a new roof assembly or over an existing roof surface (and can be applied over the top of just about anything, as long as the correct coating is selected). Factory-applied coatings are applied during the manufacturing process. Examples of factory-applied coatings include coatings applied to metal, and glazes that are applied to tiles.

- Single-Ply: Single-ply roofing is laid down in a single layer over a low or steep-sloped roof. The single-ply membrane can be loose-laid and weighted down with ballast or pavers, or firmly set on the roof and attached with mechanical fasteners or adhesives. Single-ply thermoplastic is a flexible sheet membrane which consists of compounded plastic polymers. When heat is applied onto the surface, the single-ply thermoplastic seams are melded together, making the material seamless and effective. Most thermoplastics are manufactured to include a reinforcement layer, such as polyester or fiberglass, for additional durability and strength. There are various types of single-ply thermoplastic, such as polyvinyl chloride (PVC) and thermoplastic polyolefin (TPO). PVC tends to be more expensive than TPO, but PVC is well-known for long-term performance and is naturally fire-retardant. TPO is a blend of polymers that can contain flame-retardants or UV absorbers.

- Asphalt Shingles: Although a challenging technical issue, some manufacturers have created dark-colored asphalt shingles that look almost identical to conventional shingles, yet they qualify as cool roof products. They accomplish this feat through the use of engineered pigments that reflect high amounts of invisible wavelengths, namely, infrared.

In summary, cool roofs are coatings and sheets that are applied to roofs to make them reflect the sun in order to keep building’s interior cooler and more energy-efficient, which is especially important during summer months and in warmer climates.

by Nick Gromicko, CMI® and Kenton Shepard, CMI®